Engineers Use Kirigami To Make Ultrastrong, Lightweight Structures

Eddie Gonzales Jr. – MessageToEagle.com – Cellular solids are materials composed of many cells that have been packed together, such as in a honeycomb. The shape of those cells largely determines the material’s mechanical properties, including its stiffness or strength. Bones, for instance, are filled with a natural material that enables them to be lightweight, but stiff and strong.

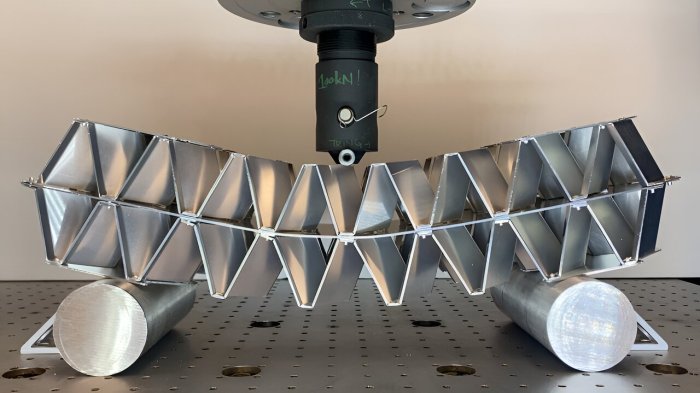

MIT researchers used kirigami, the art of Japanese paper cutting and folding, to develop ultrastrong, lightweight materials that have tunable mechanical properties, like stiffness and flexibility. These materials could be used in airplanes, automobiles, or spacecraft. Credit: Massachusetts Institute of Technology

Inspired by bones and other cellular solids found in nature, humans have used the same concept to develop architected materials. By changing the geometry of the unit cells that make up these materials, researchers can customize the material’s mechanical, thermal, or acoustic properties. Architected materials are used in many applications, from shock-absorbing packing foam to heat-regulating radiators.

Using kirigami, the ancient Japanese art of folding and cutting paper, MIT researchers have now manufactured a type of high-performance architected material known as a plate lattice, on a much larger scale than scientists have previously been able to achieve by additive fabrication. This technique allows them to create these structures from metal or other materials with custom shapes and specifically tailored mechanical properties.

“This material is like steel cork. It is lighter than cork, but with high strength and high stiffness,” says Professor Neil Gershenfeld, who leads the Center for Bits and Atoms (CBA) at MIT and is senior author of a new paper on this approach.

The researchers developed a modular construction process in which many smaller components are formed, folded, and assembled into 3D shapes. Using this method, they fabricated ultralight and ultrastrong structures and robots that, under a specified load, can morph and hold their shape.

Because these structures are lightweight but strong, stiff, and relatively easy to mass-produce at larger scales, they could be especially useful in architectural, airplane, automotive, or aerospace components.

The MIT researchers modified a common origami crease pattern, known as a Miura-ori pattern, so the sharp points of the corrugated structure are transformed into facets. The facets, like those on a diamond, provide flat surfaces to which the plates can be attached more easily, with bolts or rivets. Credit: Massachusetts Institute of Technology

Joining Gershenfeld on the paper are co-lead authors Alfonso Parra Rubio, a research assistant in the CBA, and Klara Mundilova, an MIT electrical engineering and computer science graduate student; along with David Preiss, a graduate student in the CBA; and Erik D. Demaine, an MIT professor of computer science. The research will be presented at ASME’s Computers and Information in Engineering Conference held in Boston August 20–23.

Fabricating by folding

Architected materials, like lattices, are often used as cores for a type of composite material known as a sandwich structure. To envision a sandwich structure, think of an airplane wing, where a series of intersecting, diagonal beams form a lattice core that is sandwiched between a top and bottom panel. This truss lattice has high stiffness and strength, yet is very lightweight.

Plate lattices are cellular structures made from three-dimensional intersections of plates, rather than beams. These high-performance structures are even stronger and stiffer than truss lattices, but their complex shape makes them challenging to fabricate using common techniques like 3D printing, especially for large-scale engineering applications.

The MIT researchers overcame these manufacturing challenges using kirigami, a technique for making 3D shapes by folding and cutting paper that traces its history to Japanese artists in the 7th century.

Kirigami has been used to produce plate lattices from partially folded zigzag creases. But to make a sandwich structure, one must attach flat plates to the top and bottom of this corrugated core onto the narrow points formed by the zigzag creases. This often requires strong adhesives or welding techniques that can make assembly slow, costly, and challenging to scale.

The MIT researchers modified a common origami crease pattern, known as a Miura-ori pattern, so the sharp points of the corrugated structure are transformed into facets. The facets, like those on a diamond, provide flat surfaces to which the plates can be attached more easily, with bolts or rivets.

“Plate lattices outperform beam lattices in strength and stiffness while maintaining the same weight and internal structure,” says Parra Rubio. “Reaching the H-S upper bound for theoretical stiffness and strength has been demonstrated through nanoscale production using two-photon lithography. Plate lattices construction has been so difficult that there has been little research on the macro scale. We think folding is a path to easier utilization of this type of plate structure made from metals.”

Customizable properties

Moreover, the way the researchers design, fold, and cut the pattern enables them to tune certain mechanical properties, such as stiffness, strength, and flexural modulus (the tendency of a material to resist bending). They encode this information, as well as the 3D shape, into a creasing map that is used to create these kirigami corrugations.

For instance, based on the way the folds are designed, some cells can be shaped so they hold their shape when compressed while others can be modified so they bend. In this way, the researchers can precisely control how different areas of the structure will deform when compressed.

Because the flexibility of the structure can be controlled, these corrugations could be used in robots or other dynamic applications with parts that move, twist, and bend.

To craft larger structures like robots, the researchers introduced a modular assembly process. They mass produce smaller crease patterns and assemble them into ultralight and ultrastrong 3D structures. Smaller structures have fewer creases, which simplifies the manufacturing process.

Using the adapted Miura-ori pattern, the researchers create a crease pattern that will yield their desired shape and structural properties. Then they utilize a unique machine—a Zund cutting table—to score a flat, metal panel that they fold into the 3D shape.

“To make things like cars and airplanes, a huge investment goes into tooling. This manufacturing process is without tooling, like 3D printing. But unlike 3D printing, our process can set the limit for record material properties,” Gershenfeld says.

Using their method, they produced aluminum structures with a compression strength of more than 62 kilonewtons, but a weight of only 90 kilograms per square meter. (Cork weighs about 100 kilograms per square meter.) Their structures were so strong they could withstand three times as much force as a typical aluminum corrugation.

The versatile technique could be used for many materials, such as steel and composites, making it well-suited for the production lightweight, shock-absorbing components for airplanes, automobiles, or spacecraft.

However, the researchers found that their method can be difficult to model. So, in the future, they plan to develop user-friendly CAD design tools for these kirigami plate lattice structures. In addition, they want to explore methods to reduce the computational costs of simulating a design that yields desired properties.

“Kirigami corrugations holds exciting potential for architectural construction,” says James Coleman MArch ’14, SM ’14, co-founder of the design for fabrication and installation firm SumPoint, and former vice president for innovation and R&D at Zahner, who was not involved with this work. “In my experience producing complex architectural projects, current methods for constructing large-scale curved and doubly curved elements are material intensive and wasteful, and thus deemed impractical for most projects.

Using their method, researchers produced aluminum structures with a compression strength of more than 62 kilonewtons, but a weight of only 90 kilograms per square meter. Credit: Massachusetts Institute of Technology

“While the authors’ technology offers novel solutions to the aerospace and automotive industries, I believe their cell-based method can also significantly impact the built environment. The ability to fabricate various plate lattice geometries with specific properties could enable higher performing and more expressive buildings with less material. Goodbye heavy steel and concrete structures, hello lightweight lattice.”

Parra Rubio, Mundilova and other MIT graduate students also used this technique to create three large-scale, folded artworks from aluminum composite that are on display at the MIT Media Lab. Despite the fact that each artwork is several meters in length, the structures only took a few hours to fabricate.

“At the end of the day, the artistic piece is only possible because of the math and engineering contributions we are showing in our papers. But we don’t want to ignore the aesthetic power of our work,” Parra Rubio says.

Written by Eddie Gonzales Jr. – MessageToEagle.com Staff